Address:China

Working time :Monday to Friday: 7am to 7pm

Weekends: 10am to 5pm

Address:China

Working time :Monday to Friday: 7am to 7pm

Weekends: 10am to 5pm

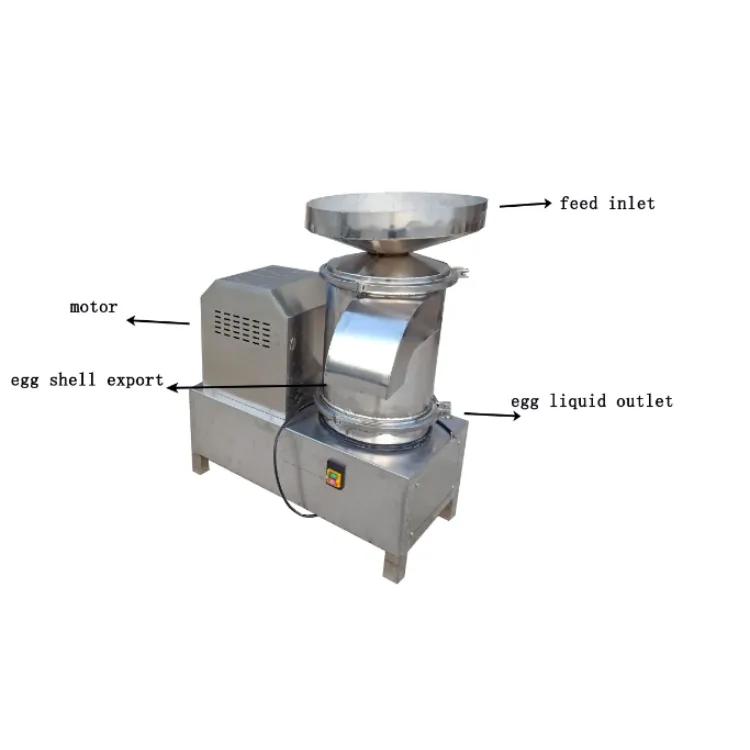

Upgrade your egg processing capabilities with the HT-C300 Egg Breaking Machine. Its stainless steel material and efficient design guarantee durability and easy maintenance. With its ability to break eggs, separate egg liquid from eggshell, and crush the shells for easy discharge, this machine is a reliable choice for egg product processing

– Model: HT-C300

– Voltage: 220V/380V/415V, 3-phase power, 2.2kw

– Output: 12000 pieces/hour, 300kg/hour

– Material: Stainless steel, the part in contact with egg liquid is 304 stainless steel

– Factory Accessories: 2 belts and 1 repairman

– Size: 900*600*1100mm

– Packaged Size: 1000*800*1400mm

– Weight: 150kg

The egg breaking machine is designed to break eggs and separate the egg liquid from the eggshell. Additionally, it can crush the eggshell into small pieces, reducing the volume of the shells for easy discharge. The machine is capable of automatically breaking whole eggs and efficiently separating eggshell and egg liquid. It finds applications in egg product processing, cake factories, large canteens, and other settings requiring the processing of a large quantity of eggs simultaneously.

Note: It is recommended to follow the provided guidelines to ensure proper functioning and maintenance of the egg breaking machine.